Part 1. What does centrifuge do?

A laboratory centrifuge is an instrument that uses the centrifugal force generated by a rotating rotor to separate substances with different densities and different particle sizes in a suspension or emulsion, or analyzes at the same time as the separation. It has a wide range of applications and is suitable for industries such as hospitals,universities, chemical industry, food, pharmacy, biology, environmental protection and so on.

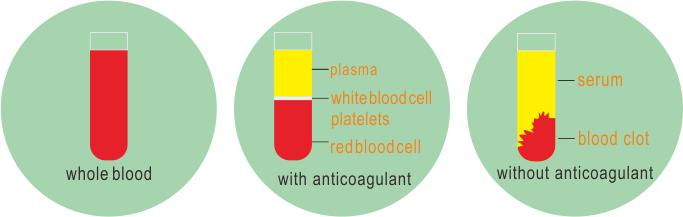

Take a blood centrifuge in a hospital laboratory as an example. Most laboratory testing items does not check whole blood, but plasma or serum. Plasma refers to blood with blood cells removed, and serum is plasma with fibrinogen removed. Plasma or serum cannot be separated directly from the blood and need to be obtained by centrifugation through a blood centrifuge/low-speed centrifuge.

To obtain serum, first let the whole blood clot at room temperature (37 degrees) for more than half an hour. Then turn on the centrifuge, and centrifuge at 3500-4000rpm for 5-10 minutes. Then remove the clot, the serum is separated.

Unlike serum, plasma is obtained from whole blood that is not left to clot and contains serum along with clotting factors. To obtain plasma, first collect the whole blood sample with the anticoagulant tube. Then centrifuge at 3500-4000rp for 5-10 minutes, remove cells and keep plasma supernatant.

Part 2. How does centrifuge work?

A centrifuge adopts the principle of centrifugal sedimentation of solution density of different particles separation, enrichment and purification.

Due to the different density and sedimentation coefficient of the sample components, during the high-speed rotation of the centrifuge, the movement caused by the centrifugal force causes the solid substances suspended in the liquid to form sediments. That is, the objects with larger mass/volume in the suspended liquid fluid move in the direction with the largest radius of the rotor, while the parts with smaller mass / volume are deposited in the place near the radius of the rotor.

In the general laboratory centrifugation process, the centrifuge tube is placed on the centrifuge rotor. The centrifugal force generated by the rapid rotation of the centrifuge tube driven by the rotor will speed up the sedimentation of the denser components in the sample to the bottom of the centrifuge tube. The sample sediment after centrifugation will form a layered structure, all you need to do is pour out the upper layer supernatant.

There are mainly 4 kinds of rotors for lab centrifuges manufactured by KETHINK.

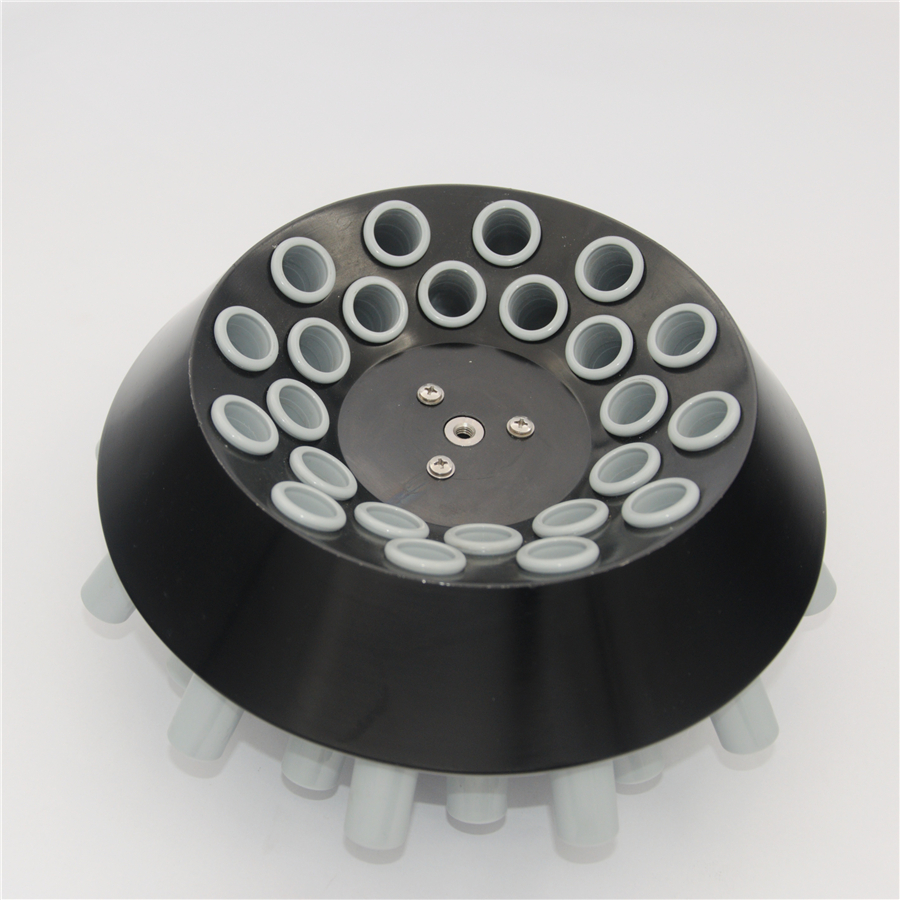

1. Fixed angle rotor

12*5ml, low speed

24*10ml,low speed

12*1.5ml/2ml, high speed

Centrifuge with a fixed angle rotor, centrifuge tubes will be placed and fixed at up to about 45°angle. During the centrifugation, particles with greater gravity will precipitate on the bottom of the tube. And along the side near the bottom wall. Wile particles with less gravity will sediment on the upper part of the tube.

2. Horizontal swing rotor

4*500ml hanging cups

96*5ml buckets

24*15ml tube sets

The horizontal swing rotor can hang large volume cups, bucket, tube set.

The swinging bucket/cup/tube set design allows the tubes to swing out from a vertical resting position to become parallel to the horizontal during centrifugation. As a result, sediment will form along the bottom of the tube.

Swinging rotors are best for separating large volume samples at low speeds and resolving samples in rate-zonal (density) gradients.

3. Horizontal Elisa plate rotor

Horizontal Elisa plate rotor is specially designed for centrifuge samples in standard Elisa plate for PCR lab.

2*48 holes Elisa plate rotor

2*96 holes Elisa plate rotor

4. Continuous centrifugal rotor

The continuous centrifugal rotor is designed for solid-liquid separation in pharmaceutical factories for mass production.

Principles of centrifugation :A method of separating substances with different specific gravities by means of centrifugal force is called centrifugation. Because centrifuges can produce a fairly high angular velocity, the centrifugal force is much greater than gravity, so the suspended matter in the solution is easy to precipitate out. Also because substances with different specific gravities are subjected to different centrifugal forces, different sedimentation speeds can cause different specific gravities. The substance is separated.

Part 3. How to choose a centrifuge

Different types of laboratory centrifuges is needed under different environment. A suitable type of centrifuge can better exert the efficiency of the centrifuge in the production process and improve industrial production efficiency.

1. Centrifuge speed

A centrifuge is a machine that generates centrifugal force. Centrifugal force is related to rotor radius, centrifuge speed, and sample quality:

RCF/g force = 1.12 * Radius * (rpm/1000)2

RCF: relative centrifugal force, measured as g force

R: radius of rotor, centimeter

RPM: centrifuge speed, measured as Revolutions per minute.

Centrifugal force is the most important parameter for customers to make a purchase decision. According to the above formula, the radius of the rotor and the quality of the sample are constant during operation. Only the speed can be changed by control. Therefore, we often describe a centrifuge by the speed, such as high-speed centrifuge, low-speed centrifuge.

Centrifuge speed below 10000rpm is classified as low-speed centrifuge, from 10000-30000rpm is high speed.

2. Centrifuge size

Centrifuge can be classified as benchtop centrifuge & floor standing centrifuge according to its shell physical dimension. Centrifuge can also be classified as large capacity centrifuge & micro-volume centrifuge according to the different maximum volume it can contain and centrifuge.

Normally a floor-standing centrifuge has a larger inner cavity to proceed large volume sample centrifuge, also has space for a refrigerated cooling system.

3. Different applications

- If the samples are temperature-sensitive, a refrigerated centrifuge is required.

- If the samples need to be processed is large in volume, then normally a floor standing centrifuge with large capacity is needed to quicken the centrifuge process.

- If the centrifuge is used in hospital laboratory/ blood bank for separating blood, normally a benchtop low speed centrifuge with 4000rpm is enough.

- If the lab space is not big enough, a benchtop centrifuge is recommended for its small size compared with floor standing centrifuge.

Part 4. How to balance a centrifuge?

1. Why do you have to balance a centrifuge?

During the operation of the centrifuge, if it is not balanced, the torque on the rotating shaft is different. and the rotor will produce greater wear on the rotating shaft. Long-term wear will reduce the service life of the centrifuge. If the unbalance value deviation is too large. it may directly damage the centrifuge, even injure the operator, and cause serious production accidents.

2. How to balance centrifuge machines?

1) Balance a fixed angle rotor

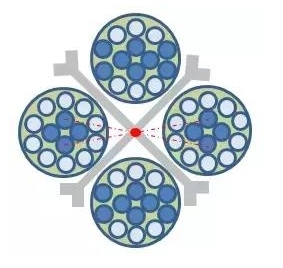

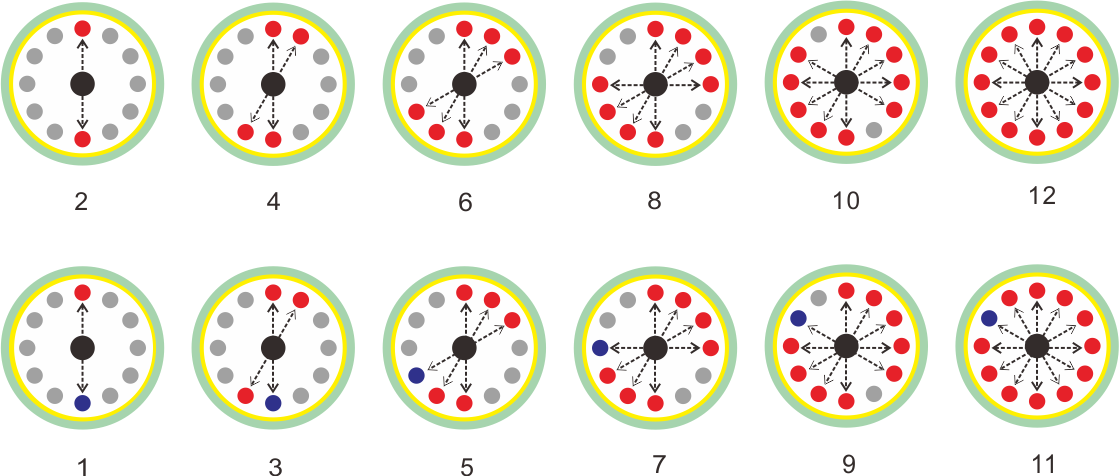

Take a 12 tube angle rotor for an example. No matter how many centrifuge tubes you need to centrifuge, always symmetrically placed them around the center of the rotor as the following picture shows.

- Make sure all samples in centrifuge tubes are evenly filled, usually lsamples in low speed centrifuge can be checked visually.While the test solution in the centrifuge tube of the high-speed centrifuge should be weighed and added.

- If an additional tube is needed for balancing, fill them with water / liquid of similar density to the sample, make sure the mass is balanced to the nearest grams. A large vibration will occur if sample volume is uneven.

- For each tube inserted in the rotor, add a tube of equal weight directly opposite it. This will ensure the center of gravity remains in the center of the rotor.

- Tighten the rotor cover(if have) and recheck whether the test tube is balanced and whether the screws are tightened.

2) Balance a horizontal swing rotor

To balance a horizontal swing rotor is more complicated than balance a fixed angle rotor. 2 aspects need to consider:

- Samples in one bucket should be balanced

- Samples in both side buckets should be balanced

Balance principle:

- Make sure that the sample in a single hanging basket/bucket is at the center point of the basket/bucket.

- Make sure that the sample in the opposite basket/bucket should be placed in accordance with the principle of center point symmetry.

3. how to balance a centrifuge with 3/5/7 tubes? / How to balance a centrifuge with odd number tubes?

One essential principle for balance a centrifuge is: if the tubes are singular and asymmetrical, i.e.3/5/7 tubes, add another empty tube and put the same quality of water into it to adjust the quality to make it symmetrical.

Part 5. When using the centrifuge, what safety precautions should be followed?

1. Ensure a sturdy, level work surface

The table surface where the centrifuge is placed should be flat, and the four rubber feet should be in contact with the table surface and be evenly stressed to avoid vibration.

2. Balance the centrifuge

The centrifuge tube should be weighed and balanced when adding liquid. If the difference, in addition, is too large, large vibration will occur during operation. At this time, stop the machine and check, make sure that the addition meets the requirements. The centrifuge tube must be placed in an even number and symmetrically. If the centrifugal test tube ruptures during operation, it will cause greater vibration and should be stopped immediately.

3. Do not open the lid while the rotor is moving

Never open the lid while the machine is working. Press “ stop” key and wait until the rotor stops moving with the speed slow down.

The time interval between restarting after each shutdown shall not be less than 5 minutes to avoid damage to the compressor due to blocking.

4. If the centrifuge vibration is large

There are mainly 3 possible reasons that may cause the machine shaking:

- Centrifuge tubes in the rotor are not placed symmetrically

Suggested solution: stop the machine and check. Make sure the tubes are balanced.

- Centrifuge tube broken

Suggested solution: replace a new tube.

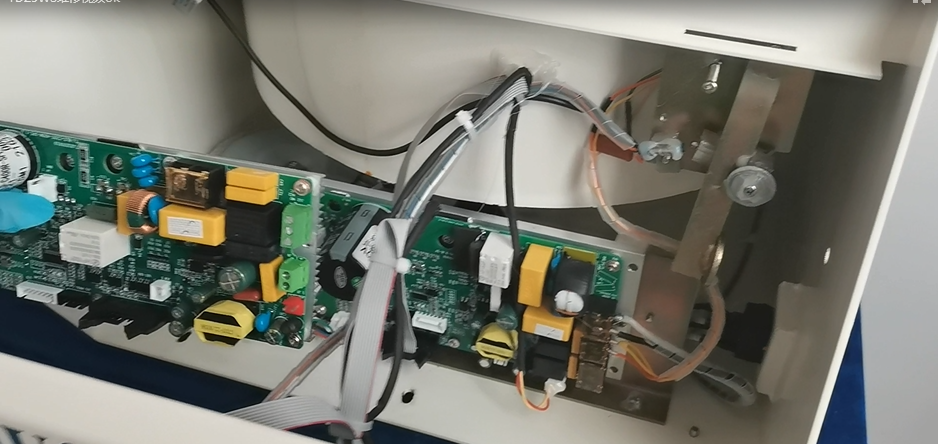

- The rotor is not rotating

| Possible Reasons | Suggested Solution |

| The door is not closed properly | close the lid properly |

| The wiring plug-in and the circuit board are loose | Plug in |

| Power supply transformer is damaged | Replace transformer |

| When the motor is energized but does not rotate, the motor or the motor module is damaged | Replace motor / module |

Part 6. How to operate a KETHINK low speed centrifuge

Take a KT-TDZ4WS as an example:

- Place the centrifuge on a flat table or table. The four rubber feet should be firmly in contact with the flat surface. Visually check to balance them. Gently shake the centrifuge by hand to check whether the centrifuge is placed smoothly.

- Open the door and put the centrifuge tube into the test tube hole of the rotor. The centrifuge tube must be placed in even-numbered symmetry (the test solution of the centrifuge tube of the high-speed centrifuge should be weighed and added). Pay attention to tighten the rotor cover and recheck whether the test tube is Put in symmetrically and whether the screws are tightened.

- Close the door cover, be sure to lock the door cover, and check whether the door cover is closed tightly afterwards. Plug in the power outlet and press the power switch.

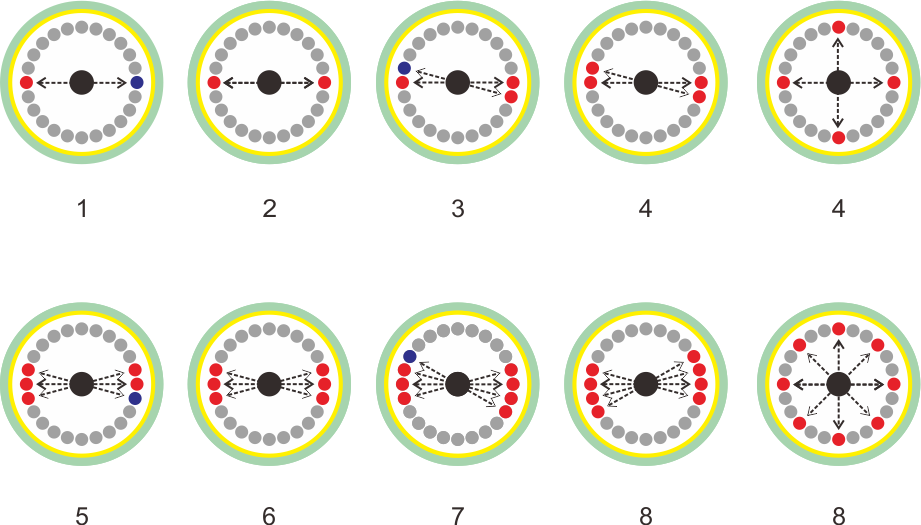

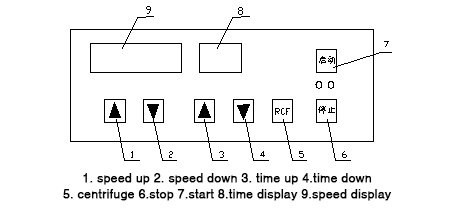

- Set the speed, centrifugal force, time: (the operation panel diagram is as follows)

- Open the door cover, install the rotor, and turn the screw.

- Put the centrifuge tube after adding liquid into the rotor, and the centrifuge tube must be placed in an even symmetry. After the centrifuge tube is placed in an even number, gently rotate the rotor body by hand to make the centrifuge hanging cup or tube rack operate flexibly.

- Close the door cover, pay attention to lock the door cover, check whether the door cover is closed tightly by hand after finishing, otherwise it will not operate.

- Plug in the power socket and press the power switch (the power switch is on the back of the centrifuge and above the power base).

- Set the speed and time:

- Set the speed: press the “▲” or “▼” key to determine the speed of the centrifuge at this time (the maximum speed is 4000r/min), when the speed reaches the speed required for this experiment, release the button. After the speed number flashes for 3 seconds, the parameters set this time are automatically confirmed.

- Setting time: press the “▲” key to set the speed upwards, press the “▼” speed to set downwards, after the setting is completed, the display flashes twice to indicate the setting is successful, and then press the “▲” or “▼” key to confirm The working time of the centrifuge this time (the longest time is 99 minutes), the time is countdown.

- After the above two steps are completed, press the “confirm” button to confirm the speed and time set above, and then press the “start” button to start the centrifuge. After the centrifuge starts to run, the speed and remaining centrifuge time will be displayed on the control panel.

- When the centrifuge time counts down to “0”, the centrifuge will automatically stop. When the speed is equal to 0, the buzzer will sound; press the “Stop” button during operation, the centrifuge will stop running, and the buzzer will not sound .

- During operation, if you want to convert the centrifugal force, press the “start” button (RCF light is on), the centrifugal force at the current speed will be displayed, and it will automatically return to the running state after 3 seconds.

- When the rotor stops, press the “stop/door” button to open the door and take out the centrifuge tube.

- Turn off the power switch after use.

Part 7. How do you maintain a centrifuge?

The centrifuge is a precision instrument in the laboratory. So daily maintenance is essential, and it needs to be cleaned after each experiment.

1. Centrifuge care and maintenance

● The centrifuge should be placed on a stable table to prevent it from sliding or vibrating and causing accidents.

● Accelerate gradually when starting the centrifuge. When the sound is found to be abnormal, stop the machine for inspection and troubleshoot (such as centrifuge tube asymmetrical, unequal quality, centrifuge position is not level or the screw cap is loose, etc.) before working.

● Centrifuge tubes should be placed symmetrically. If the tubes are singular and asymmetrical, add another empty tube and put the same quality of water into it to adjust the quality to make it symmetrical.

● The casing of the centrifuge should be kept clean, and the bottom of the casing should be lined with soft materials such as foam to prevent the centrifuge tube from being broken.

● When turning off the centrifuge, slow down gradually until it stops automatically. Do not use forced methods to stop it.

● Make suer the cetnrifuge lid is closed properly & firmly before start.

● The wear of commutator and brush should be checked regularly (about one year), and those with excessive wear should be replaced immediately.

● The bearings of the motor should be regularly filled with lubricating oil (for example: Vaseline).

● Perform maintenance inspections once a month and fill in the instrument maintenance records.

2. Centrifuge Cleaning

● Clean the inner cavity and rotor with a damp cloth to see if there is any residue;

● Deep maintenance: check the speed, temperature, sound, etc.

Part 8. Troubleshooting

KT-TDZ5WS Low Speed Centrifuge (horizontal rotor)Disassembly & Assembly Video

Common faults and troubleshooting methods

| Faults | Possible Reasons | Suggested Solution |

| After the power switch is turned on, The display window is not bright | no 220V power | check power supply |

| fuse burnt | check & replace | |

| the transformer power plug-in and the control board are loose | plug in | |

| Press the start button, the rotor does not run | the door is not closed properly | close properly |

| the wiring plug-in and the circuit board are loose | plug in | |

| power supply transformer is damaged | replace | |

| when the motor is energized but does not rotate, the motor or the motor module is damaged | replace motor / module | |

| the circuit board is damaged | contact manufacturer | |

| Centrifuge vibration is large | centrifuge tubes in the rotor are not placed symmetrically | check & adjust |

| centrifuge tube broken | check & replace | |

| the rotor is not rotating | check |